Apollo A300C Mid-Range Rear Loader

Large Hopper, Low Loading Height, “E-Z Load” Productivity.

Where maximum mobility meets highest productivity in a mid-range hopper. Filled with E-Z Pack durability, reliability and features, the Apollo A300C rear loader offers quick cycle times and three modes of compaction. The A300C packs a punch well above its weight. It’s mid-range capacity with a heavy-duty attitude.

Science of Simplicity™

• Simple, straightforward controls make training/operation easy

• Minimal hydraulic and electric lines, junctions and fittings

• Simplified field diagnosis and repair

• No complex computers or PLC to fail

Maximum Payloads and Productivity

• Smart steel engineering reduces overall weight for max payloads

• Customer-tuned Product Optimization

In-the-field Reliability and Durability

• 10/60/20 Testing and Validation™

• Zinc-dichromate-plated tubing/unpainted hydraulic lines

Also available with patent-pending, Integrated CNG Fuel System.

Standard Features

• Manual Controls

• Tailgate Props

• Back-up Alarm

• Body Lifting Eyes

• High Mount Light Package

• ICC Lights and Reflectors Meet DOT Requirements

• Non-Skid Riding Steps at Rear Corners of Tailgate

• Streetside and Curbside Buzzers

• Automatic Latch-Unlatch Tailgate

Optional Equipment

• Air Shift or Hot Shift PTO’s

• Street-side Access Door

• Front Mount Pump

• Dual Hopper Flood Lights

• Rear Body Side Liner

• 10,000 lb. (4536 kg) Overhead Winch*

• 14,000 lb. (6350 kg) Reeving Cylinder Winch*

• System Pressure Gauge

• 1-3 Yard (.76 - 2.3 m3) Hydraulic Container Attachment

Operational Features

• COMPACTION CYCLE: Manual hydraulic, automatic split cycle, fully reversible

• CYCLE TIME: 26 seconds, reload @ 9 seconds

• PACKER PANEL: Curved, one-piece construction

• EJECTOR PANEL: Travels in steel guide shoes, floor-level track

• PACKING CYLINDERS: Positioned away from refuse for trouble-free operation

• EJECTOR CYLINDER: Heavy-duty, double-acting, telescopic

* Optional Container Dumping Devices Handle Containers up to 10 Cubic Yards (7.6 m3)

Your truck, customized.

Customer-Tuned Product Optimization™

In a world of manufacturing bent on dictating what you need, we’re different. We’re a company of collaborators, led by former operators, who know that many of the best ideas come right out of the field, from customers—not corporate boardrooms. We pride ourselves on our agility and ability to accommodate customer requests with their orders—everything from moving a component a few inches, to innovating a game-changing design feature.

With Customer-tuned Product Optimization, you tell us what you need and the mission you want your equipment to accomplish, and our sales and engineering team will work with you to innovate the optimal solution to improve your productivity, efficiency and profitability. Customer-tuned Product Optimization—our products, built for your idea of success.

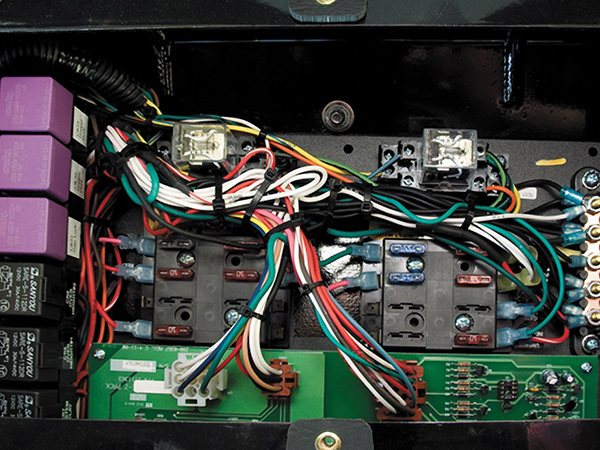

NO ONBOARD COMPUTERS MAKE IT SIMPLE

SIMPLE, EASY TO USE INTEGRATED CONTROLS

CLEAR SIGHTLINES

GLADIATOR CYLINDERS